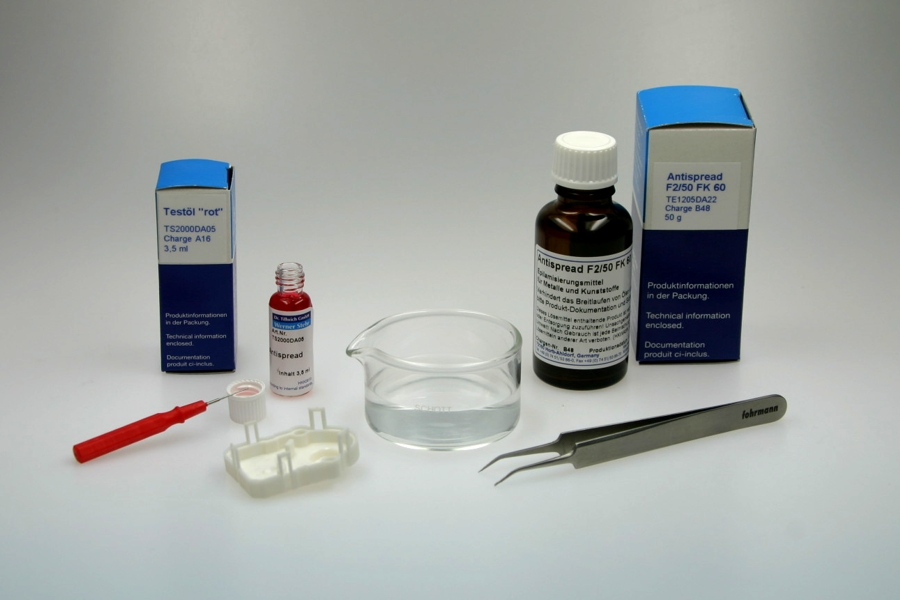

A smart method of preventing lubricants from creeping.

Safety and a long service life for assembly groups that are in contact with lubricants.

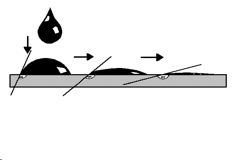

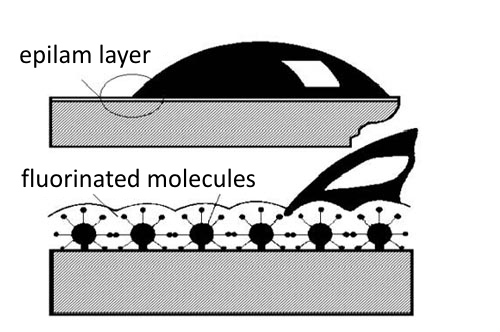

Functional principle:

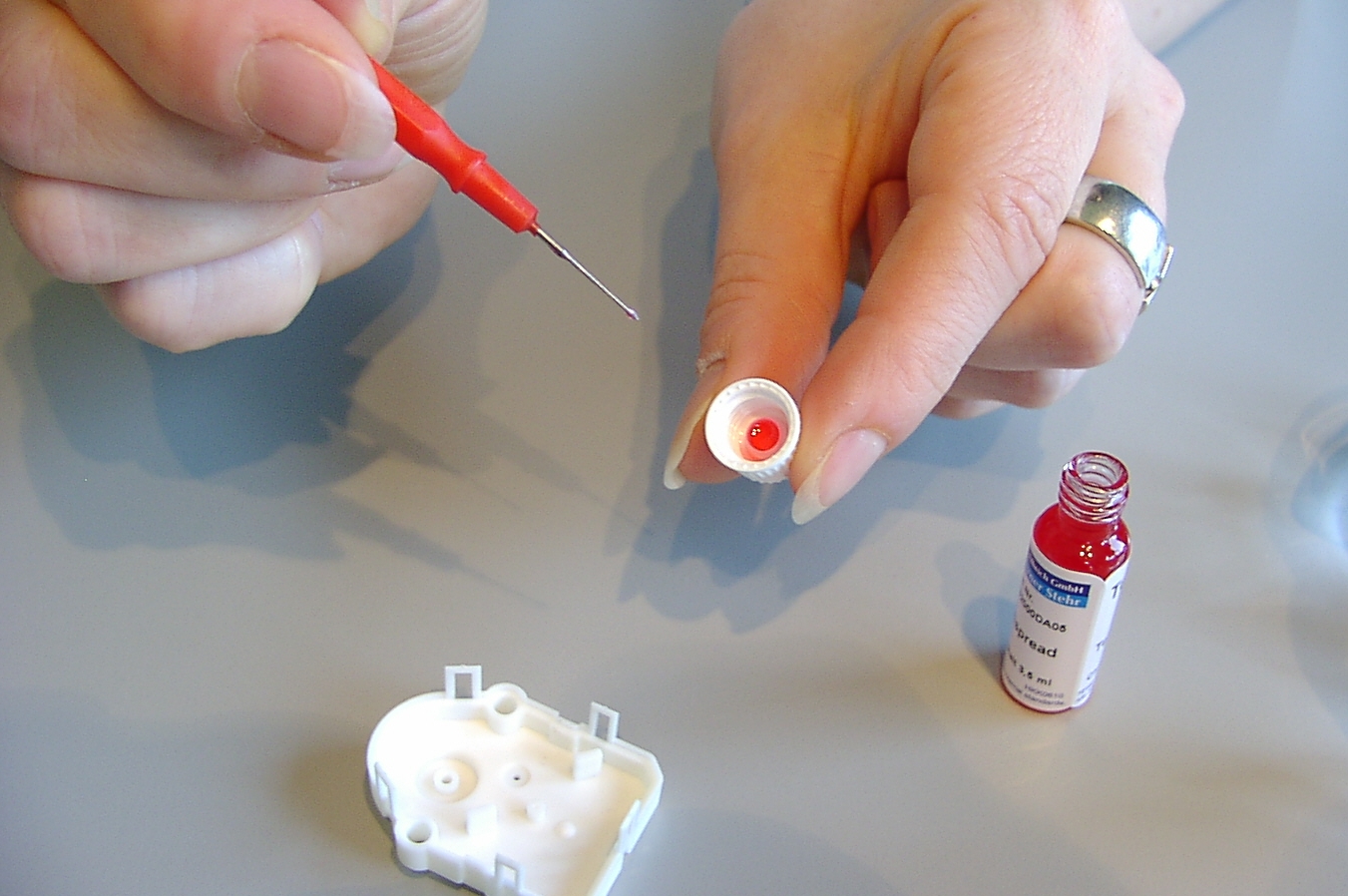

Non epilamized surface

Drop of silicone oil after 24 hours at 85°C:

very severe wetting.

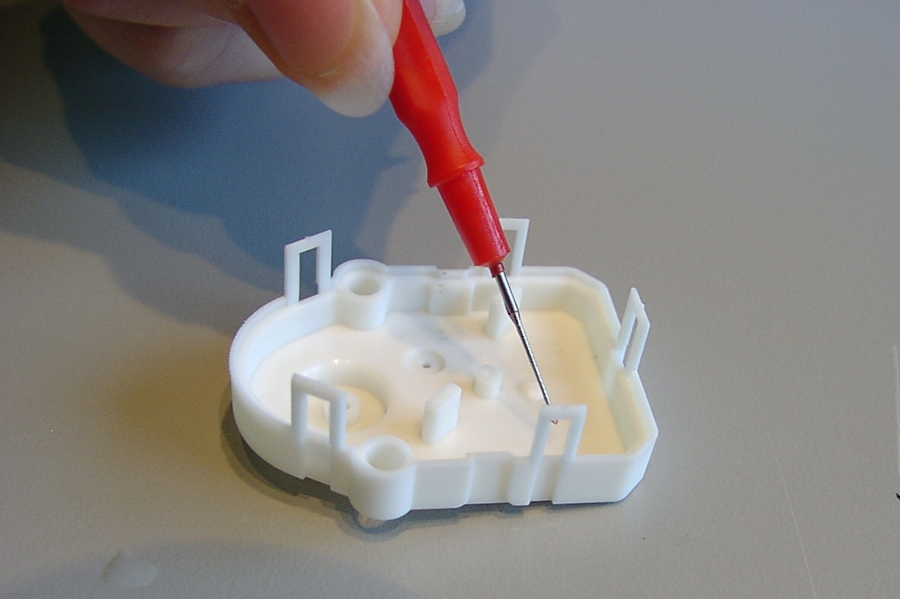

Epilamized surface

Drop of silicone oil on epilamized

surfaces remains absolutely fixed.

Parameters: 24 hrs., 85°C

Epilamization fixes lubricants.

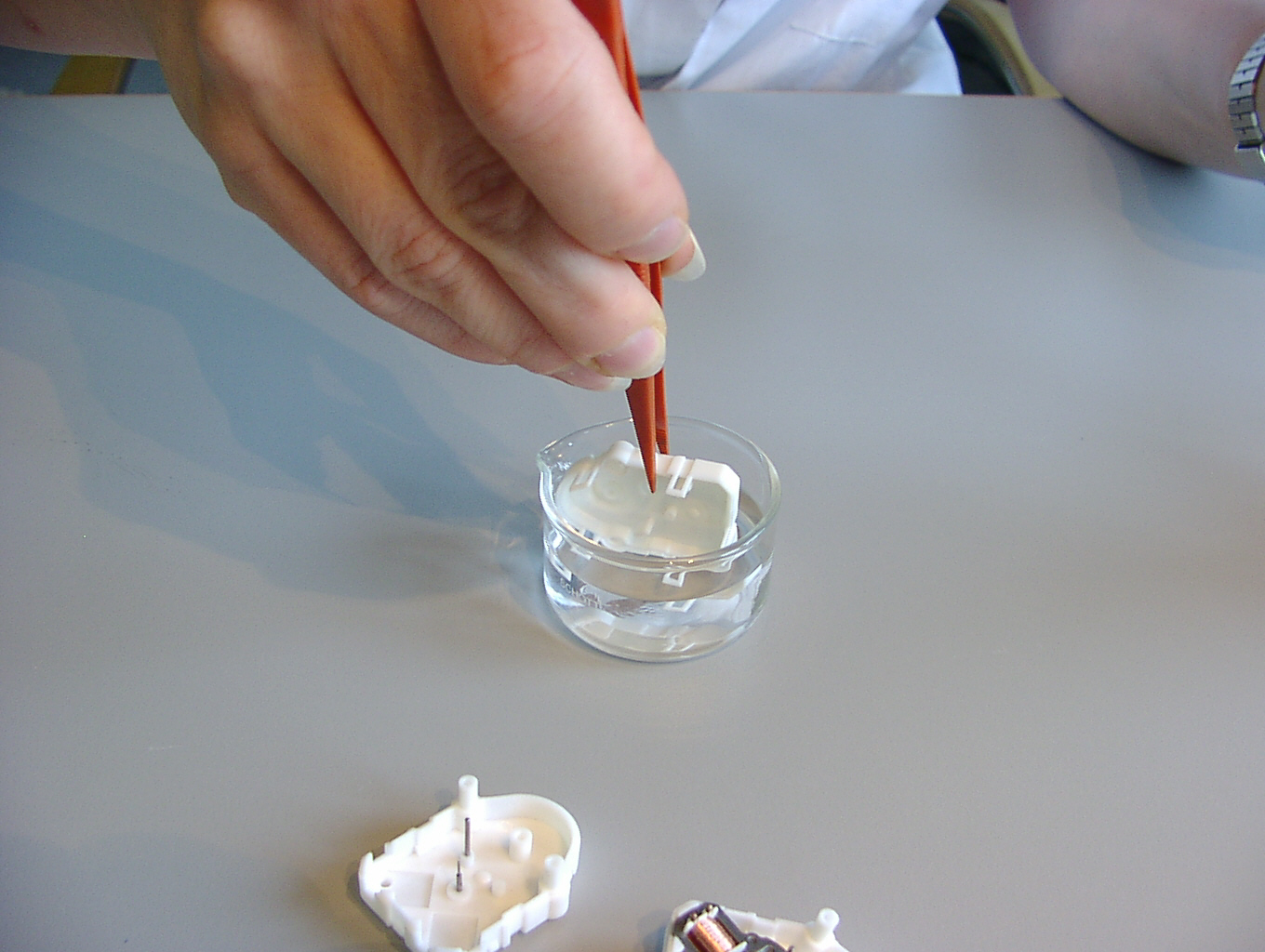

The upper half of housing of a stepper motor is being epilamized. A drop of the test fluid (silicone oil) spreads our completely on the non treated surface. The drop stays fixed on the epilamized area.

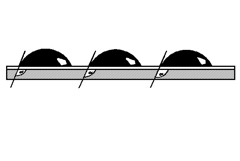

The epilam molecules form a fluorine brush with oil-repellent properties. Oil can no longer creep over this "brush".

Benefits of epilamization:

The epilamization of component surfaces that are to be lubricated may prevent lubricant loss or starved lubrication.

Lubricants cannot creep up on epilamized surfaces. Sensitive components remain lubricant-free as a result, thereby preventing possible contamination or damage.